|

First, I want to say I have done this joint a total of

two times for box lids before doing this tutorial so I am no expert on it

by any stretch of the imagination. Please keep this in mind. Also, for those

of you who want to know about the tenioning jig I use, it is the one from

Doug Stowes book and it really works well. Now having said that, let's start

with some stock. For this joint, I am using some scrap that is 3/8"

thick and ripped to 1 3/8" wide. Always cut some extra pieces for set-up

purposes. |

|

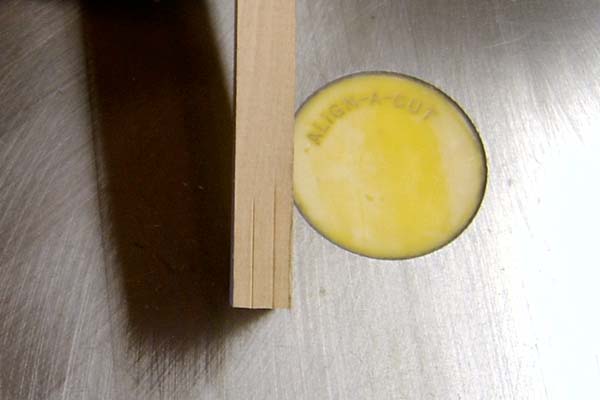

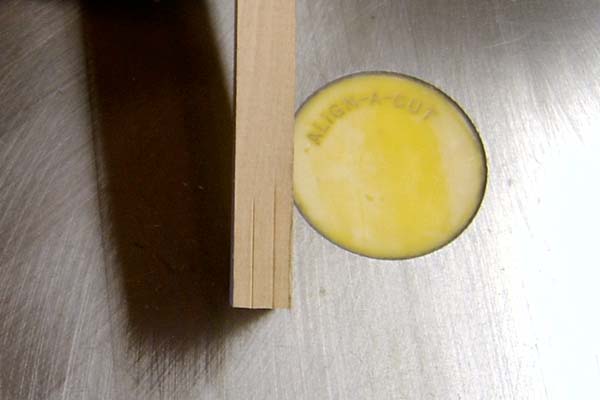

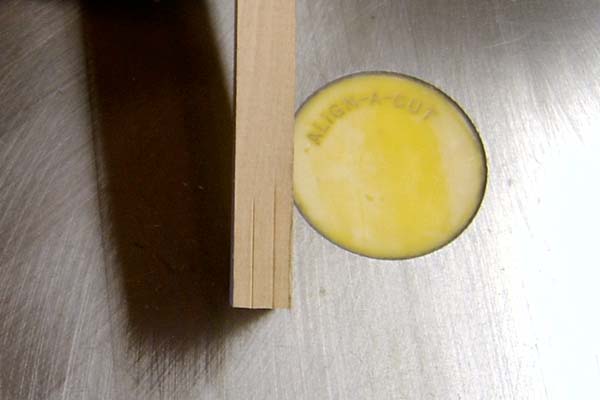

Set your table saw blade to the width of the stiles/rails.

For a standard bridle joint, set the saw a bit higher to leave some cleanup.

For a mitered joint, I think it is easier to get the 45* cut right on if

the saw is set dead on. |

|

Divide one of the scrap pieces into thirds. |

|

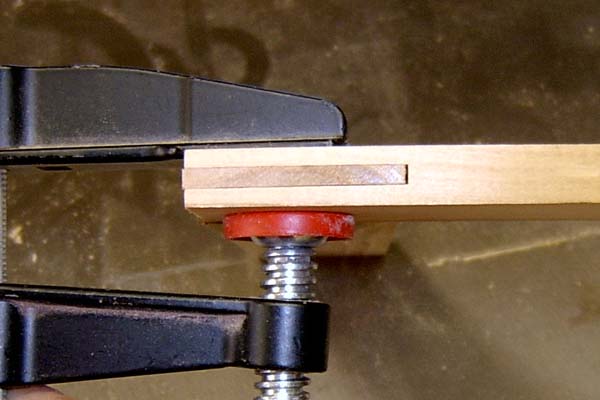

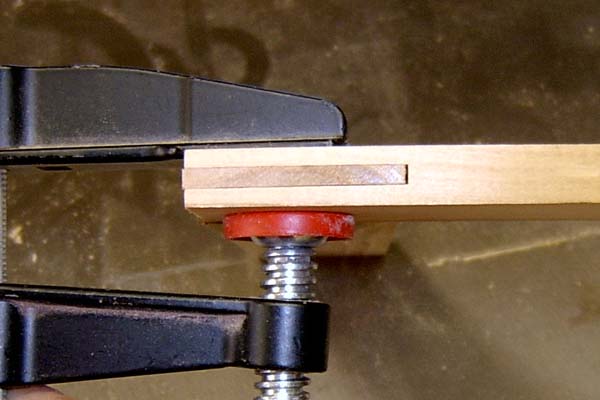

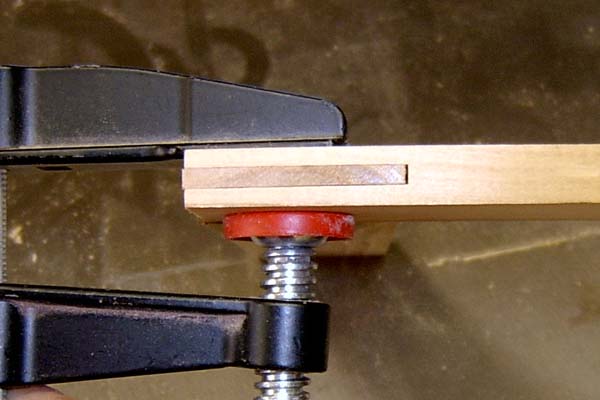

Put the piece in your tenioning jig and set the fence so

the blade is centered between the marks. If your center groove is wider

that your saw blade, set the blade to cut on the inside of the outer line.

That way, you can turn the piece around 180* and cut the other side out

and have the cut centered exactly. |

|

Cut the groove on one end and check to see if it is centered.

If not, either turn the piece around 180* and run it through the saw again

or reset the fence and try it on the other end. Once centered, cut a groove

on both ends of your rails. |

|

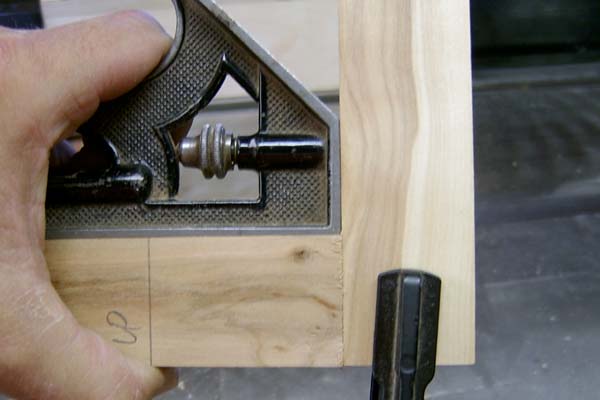

Now, using your just cut rail, set the fence so your blade

will remove just a little under the thickness of the finger on the rail.

I like to cut just under and sneak up on the right thickness rather than

have it to loose to start with. |

|

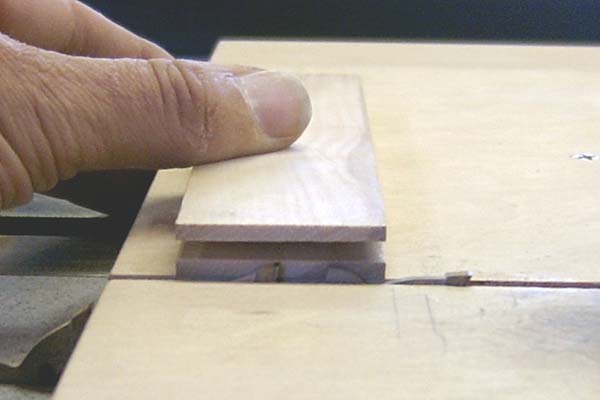

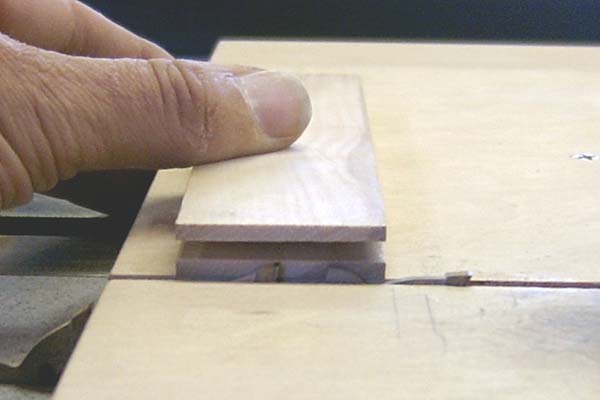

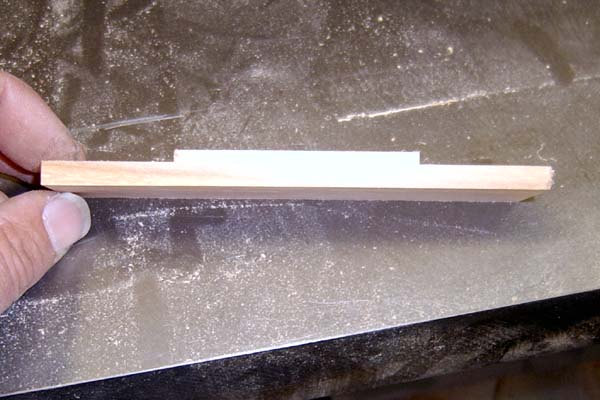

Take another piece of scrap and cut both sides. Then see

if it fits. This is just a bit to thick still, so I move the fence a touch

and try again. I repeat the proccess until I get a snug, but not tight,

fit. |

|

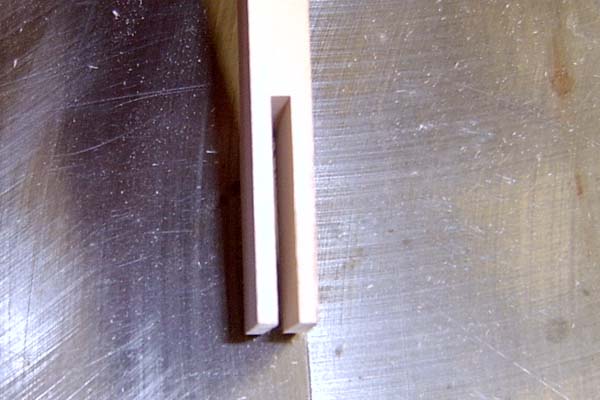

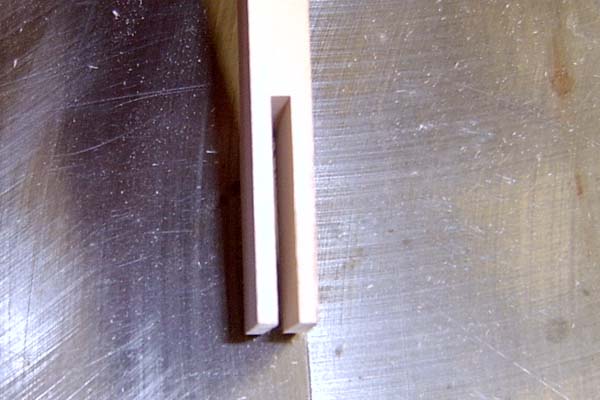

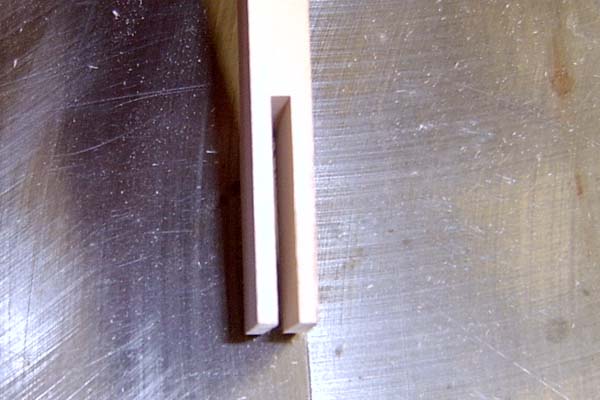

A view if the test pieces. They are square and fit tight. |

|

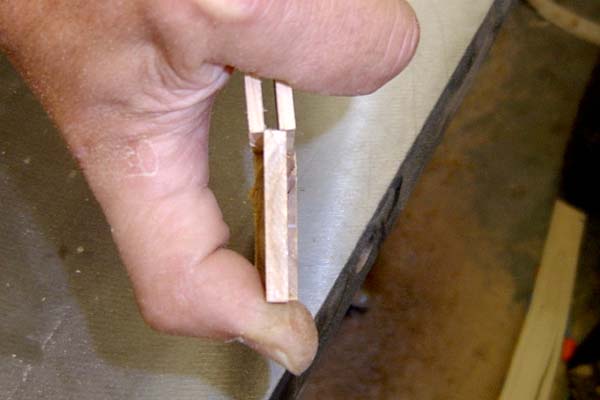

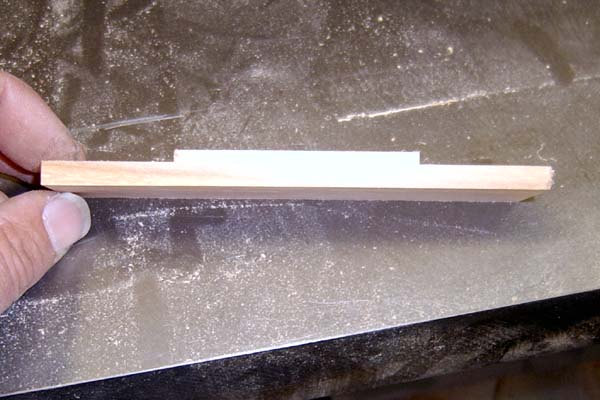

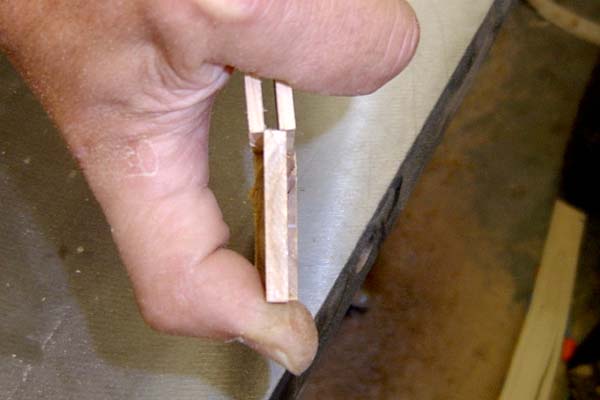

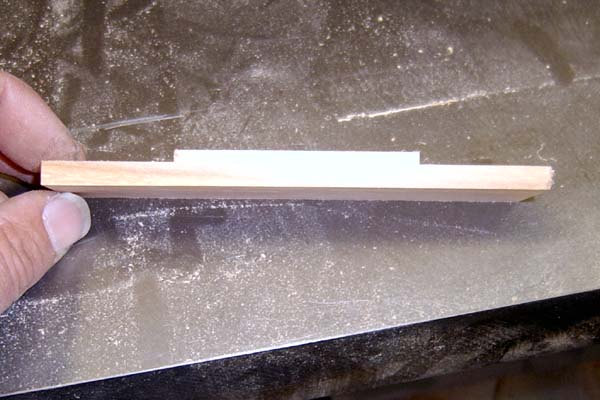

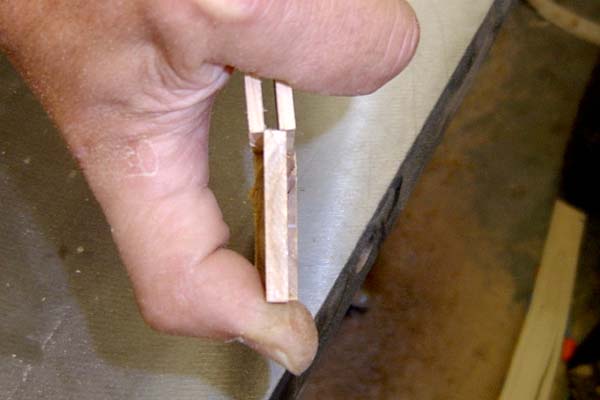

An end view of them. Looks like a bit of clean up and they

will be good. If you were going for a standar Bridle joint, now is the time

to cut the end of your stiles and your joint would be complete. |

|

If you are going for the mitered Bridle joint, just cut

the inside of the stiles only. |

|

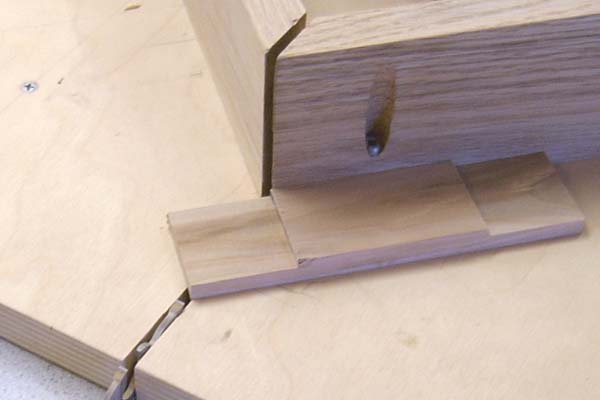

Now I grab my 45* sled and set the table saw blade height

to the thickness of the finger on the rail. I then cut the outside finger

off at 45*. Accuracy is crucial! If you don't take enough off, the stile

and rail will not come together on the bottom of the joint. This is no problem

to fix. Just take a little more off the 45*. However, if you make the cut

to far into the piece, the bottom of the pieces will not come together and

is much more difficult to fix. While making the cut, I watch to see if the

saw blade is set to high or not. In this case I saw it was by maybe 1/64".

I lowered the blade a touch before I cut the 45* on the stiles. Again, I

feel it is easier to remove a little wood rather than have the pieces fit

to loosely together. |

|

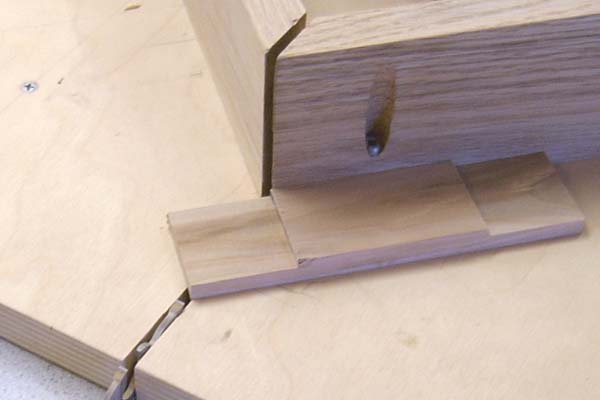

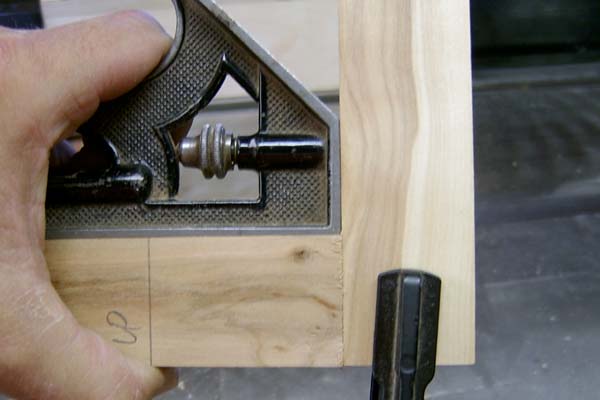

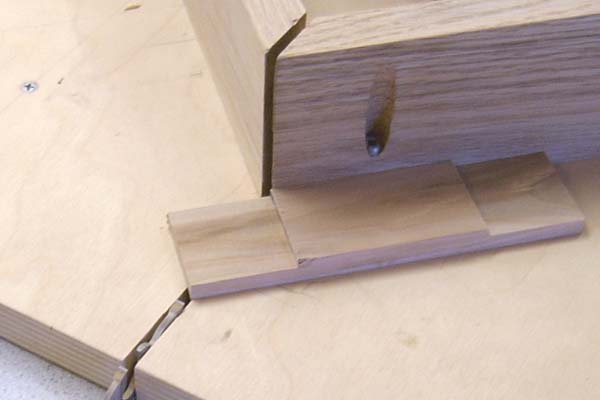

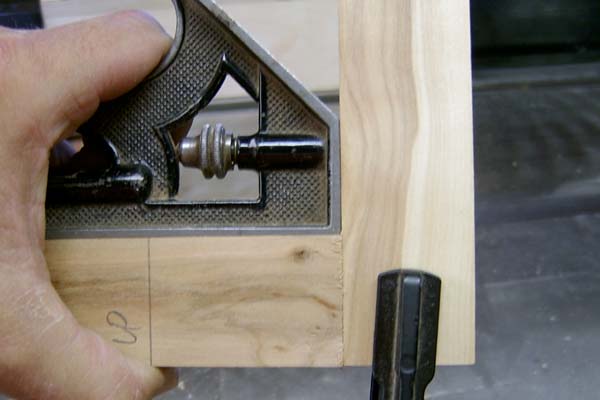

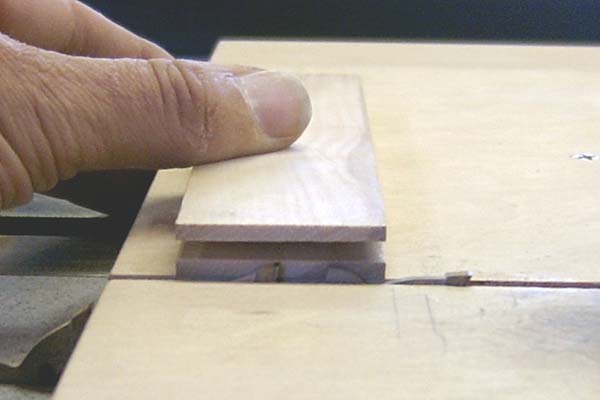

I now start to remove the wood on the stiles. I start from

the inside corner and work my way out making repeated cuts to remove all

the wood. |

|

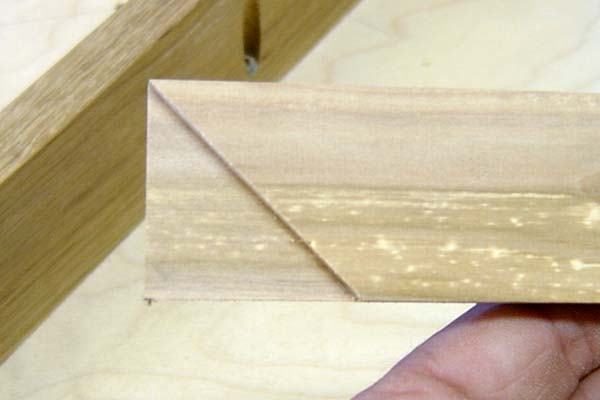

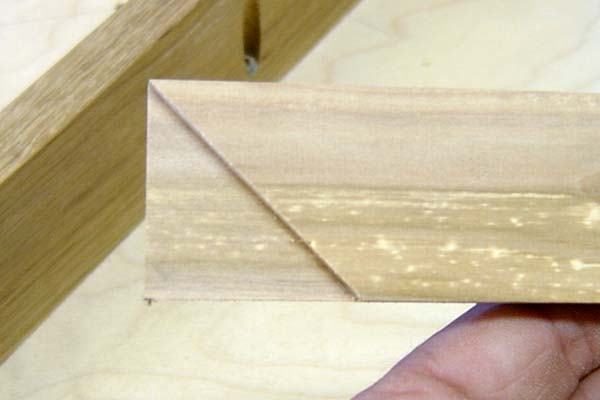

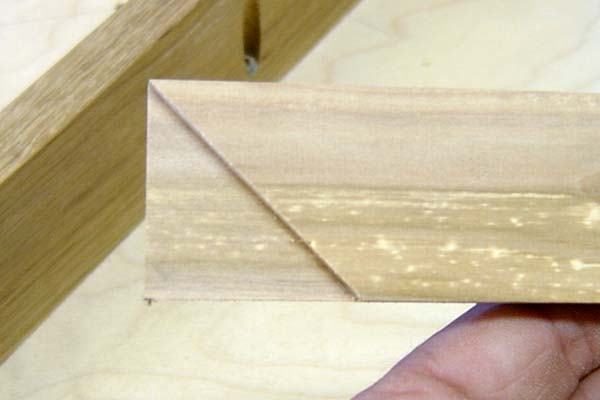

A top view of the mitered cut. |

|

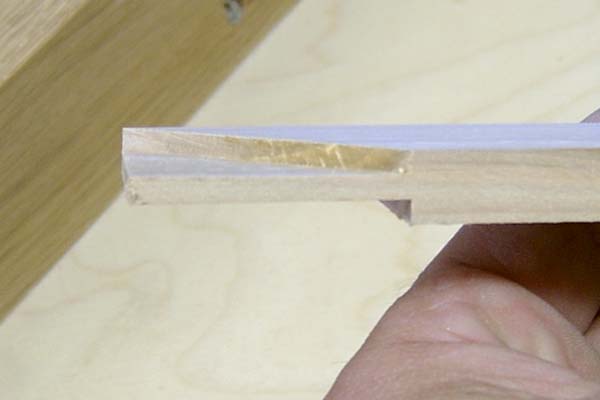

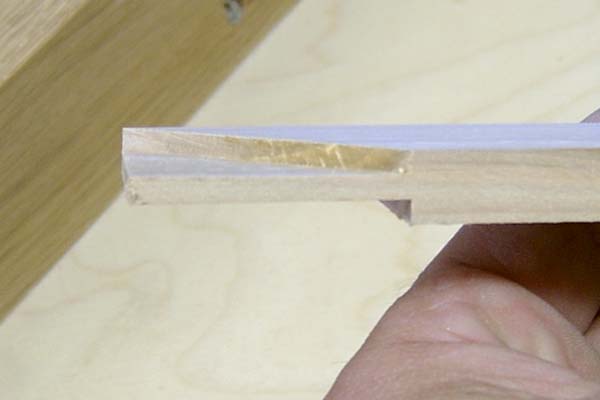

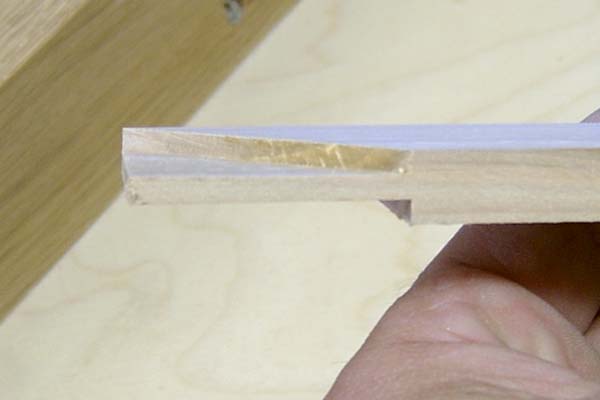

And a side view of the same piece. |

|

The fit was a bit to tight so I take the piece to my sanding

board and sand it until I get the fit just snug. I would use a plane to

do this but I am still not good enough in the use of my rabbett plane yet. |

|

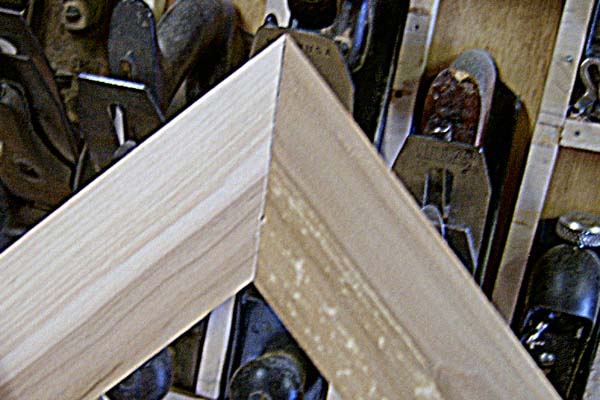

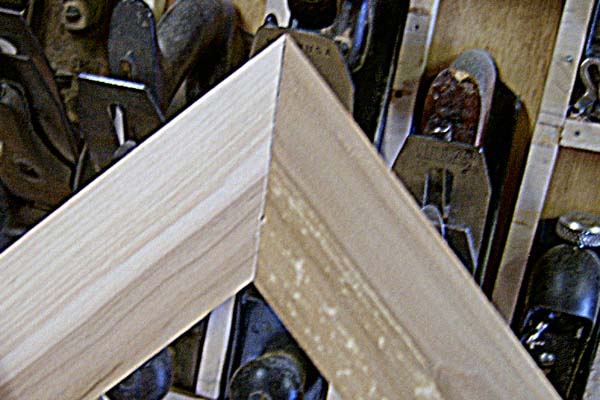

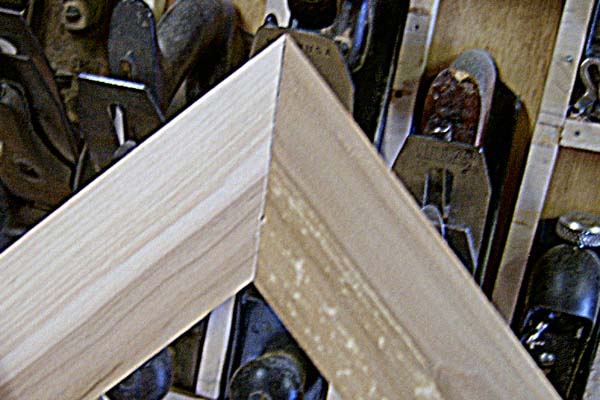

And here it is! This is the completed joint. Well not quite

completed. It needs to be worked a bit as there is a bit of a twist to it.

The inside corner on one piece is a bit higher than the other. But when

pulled together tight and square. the miter closes up very nicely. |

|

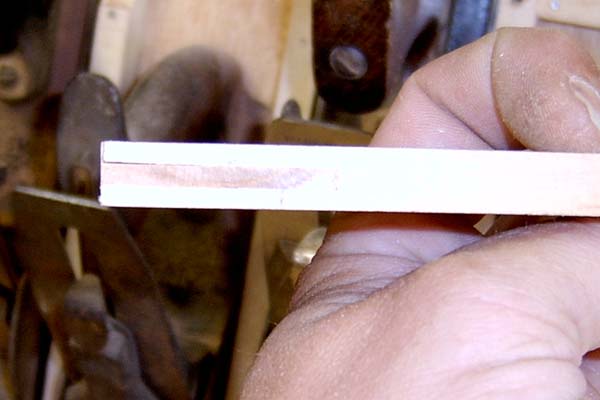

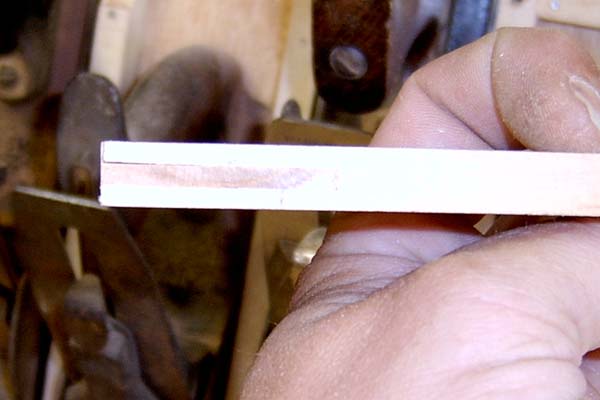

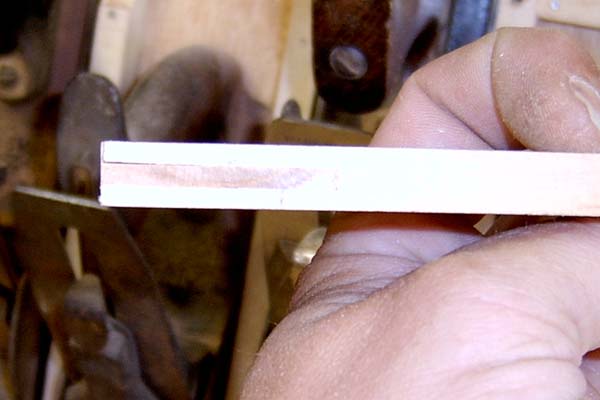

Here is the underside of the joint. A bit of clean-up and

it will be good. |

|

And last is the side view. I hope this tutorial helps answer

any questions on how I make this joint. |